Introduction

This product is a milky white liquid obtained by reacting hollow silica nanoparticles with active groups with organic matter. It is coated on the glass surface by roller coating process, and after medium temperature curing and high temperature sintering, the organic matter is completely burned off, the nanoparticles will be precisely combined with each other and rely on the hollow structure of the silica nanoparticles to produce a lower refractive index of the film layer.

Parameters

|

Item |

Standard Parameters |

Test Conditions |

|

Appearance |

乳白色 milky white |

Visual Assessment |

|

pH value |

4±1 |

pH Indicator |

|

Relative Density(g/ml) |

0.82±0.05 |

specific gravity method |

|

Solid content(%) |

3.0±0.4 |

120℃,2 hours |

|

viscosity(cps) |

2.0±0.5 |

25℃ |

Performance indicators

Appearance

milky white liquid

Transmittance

Transmittance increased by more than 2.3% on the basis of ultra-white glass, within the broadband wavelength range of 400-1100nm (measured by using the Beijing Taibo GST air-floating desktop series of transmittance testers).

Reliability Index

|

Items |

Procedures |

Frame of Reference |

Results |

Notes |

|

high temperature and humidity |

1000 hours |

JC/T 2170-2013 |

T attenuation <1% |

Compliance with industry standards |

|

Salt spray test |

96 hours |

JC/T 2170-2013 |

T attenuation <1% |

Compliance with industry standards |

|

Wet freezing test |

10 cycles |

JC/T 2170-2013 |

T attenuation <1% |

Compliance with industry standards |

|

Thermal cycling test |

200 cycles |

JC/T 2170-2013 |

T attenuation <1% |

Compliance with industry standards |

|

UV test |

Accumulated 15kw.h/m2 Total radiation at time |

JC/T 2170-2013 |

T attenuation <0.8 |

Compliance with industry standards |

|

PCT Accelerated Aging Test |

48 hours |

JC/T 2170-2013 |

T attenuation <0.8 |

Compliance with industry standards |

|

Pencil hardness |

≥3H |

JC/T 2170-2013 |

No visible scratches |

|

|

Acid resistance |

24 hours |

JC/T 2170-2013 |

T attenuation <0.8 |

Compliance with industry standards |

|

Adhesion Test |

Cross-cut test |

JC/T 2170-2013 |

grade 0 |

|

Process Requirements

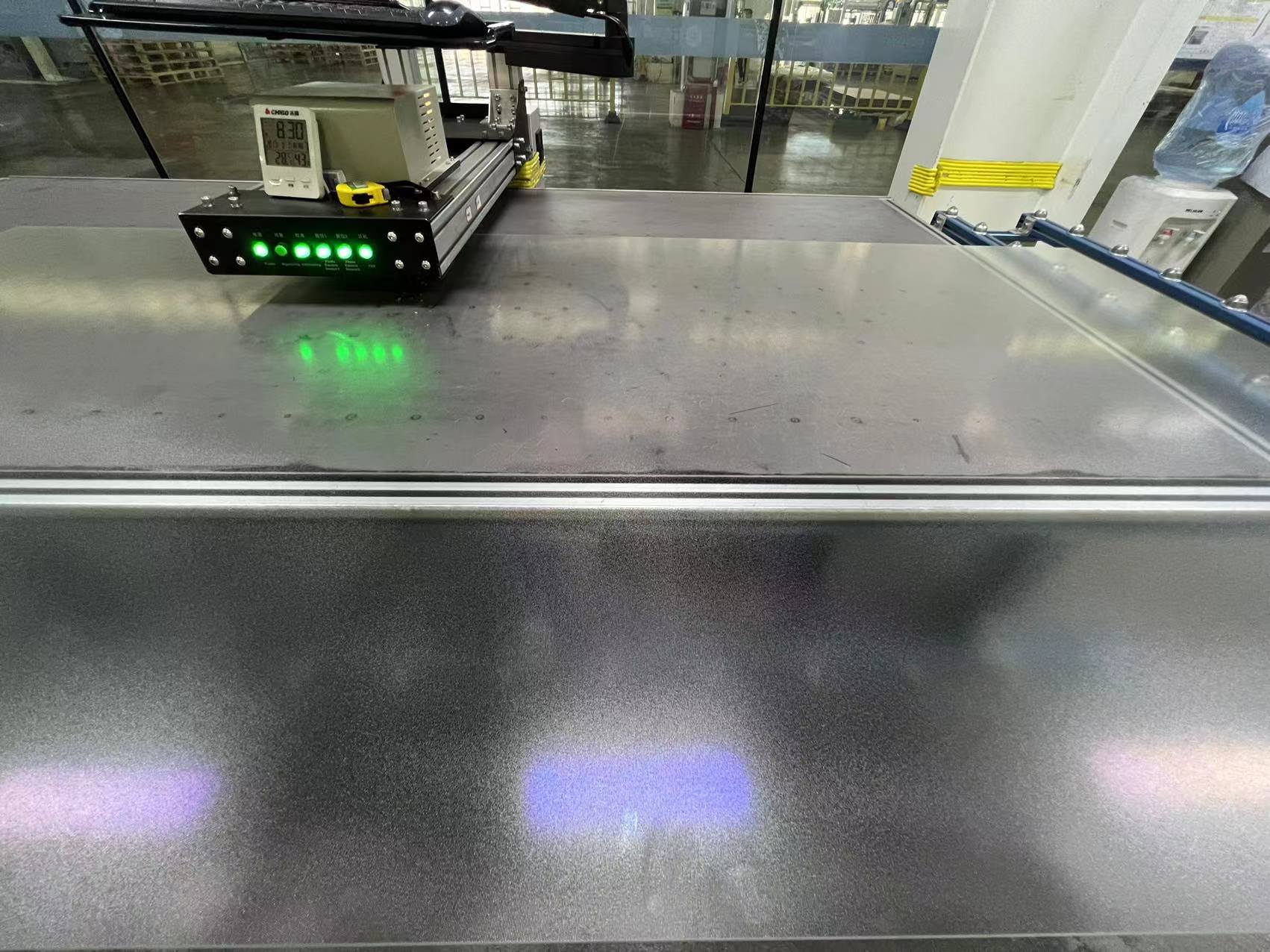

The coating solution is applied using a roll coating process.

Coating rollers should use PU rollers, the hardness should be 35 degrees -38 degrees is appropriate, coating quantitative roller is recommended to use 80-100 mesh.

Coating film temperature 20-25 degrees.

Coating film humidity ≤ 45 degrees (high humidity board surface is easy to be uneven).

Diluent: Isopropyl Alcohol (small closing print) or anhydrous ethanol.

Roller printing elimination methods: rubber roller lap dust-free cloth or chamois cloth.

When the film is formed, if the humidity of the coating room is too high or the glass surface is not air-dried, the film surface will be easily atomised after the film is formed and the light transmission rate will be reduced.

Precautions

The coating solution is a solvent-based (alcohol) nanosol system and is non-toxic. Due to the strong volatility of anhydrous ethanol contained in the solution, gloves and masks should be worn during use and regular fresh air should be used to avoid breathing contact or excessive inhalation causing dry skin and throat and eye discomfort.

the product should be stored at 25 degrees centigrade below, can be maintained for 3 months, the storage process should be avoided contact with fire and strong light source direct sunlight, so as not to cause fire or heating solution aging.