Rapid Delivery for Automatic Spray Coating Machine - Water-base Microlayer Corrosion Protection Coating (chrome free) – Junhe Detail:

Minimum Order Quantity:100 Kilograms

Packaging Details:

Pack A:16kg/ Metal Barrel

Pack B:24KG Plastic Barrel

Pack C:Based on the amount of B agent A

Delivery Time: Ten days after receipt of advance payment

Payment Terms: L/C, T/T

Supply Ability: 2 Tons per Day

Color: Silver

Coating Method: Dip-spin & Spraying

PH(20℃): 5.0-8.0

Specific Gravity: 1.30-1.40 (spray Coating)

Viscosity: According To Operating Demand.

Operating Temperature: 22±2℃

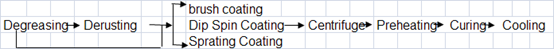

Coating Process

1.Mix Ratio

Pack A: Pack B: Pack C=1:1: X(according to different viscosity demand )

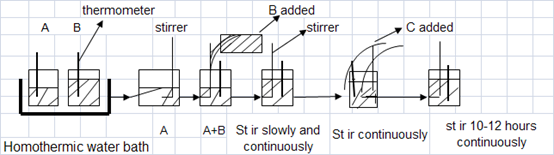

2.Before Mixture, Keep weighted A&B into the water bath at 20-25℃ , then stir A to make metal slurry disperse uniformly by frequency mixer ,after A is fully evenly dispersed, and add B.

3.Stirring A,add B along the wall of the barrel A slowly, add B in 2-3 batch.

4.Speed up striing after B added, make sure the coating paint is fully mixed,then add C. C should be powdered if lump exist.(The barrel temperature should not be lower than 30℃, otherwise C will not be dissolved sufficiently .)Then stir 12 hours alowly and continuously.

5.The coating should be filtrated by 80 mesh stainless steel screen before pouring into dip barrel.

6.Temperature control device should be equipped with dip barrel to keep the temperature of coating at 20±2℃.(If temp. is too high, the paint is liable to deteriorate, and viscosity will be effected.) The coating should be stirred circularly to keep evenly dispersed.

7.Test Specific gravity、PH、Temperature、Viscosity of coating every 8 hours if operate continuously.

Mix Diagram

Attentions

Other chemicals such as any kinds of acid, alkali salt can not be mixed into coating, for these can activate Zn & Al plate to aging the coating.

Avoid irradiation of sunshine and ultraviolet ray for long time when operating, otherwise it will accelerate aging or polymerization of the coating .

It is very important to control the temperature of coating. If the temperature of coating changes when operating, it will effect the viscosity, then effec the coating quatity on workpiece. So the relations among temperature,viscosity and spinning process shoud be controlled well when coating.

The viscosity will be different if coating method is different. Choose low data if spray coating,and choose high data if dip spin coating.

Technical Data

| No. | Item | Data |

| 1 | PH | 6-7.5 |

| 2 | Specific gravity (20℃) | 1.35±0.1 (spray coating) |

| 3 | Viscosity | 100-200s 20°C ZAHN #2 |

| 4 | Operating temperature | 20±2℃ |

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Rapid Delivery for Automatic Spray Coating Machine - Water-base Microlayer Corrosion Protection Coating (chrome free) – Junhe , The product will supply to all over the world, such as: Botswana, Tunisia, Hungary, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.