Online Exporter Zinc Flake Coating Machine - Single Group Silicon Slice Detergent JH-1017 – Junhe Detail:

Minimum Order Quantity: 500 Kilograms

Packaging Details: 1000kg/barrel

Delivery Time: Ten days after receipt of advance payment

Supply Ability: 2 Tons per Day

Color: Colorless To Yellowish Liquid

Specific Weight: 1.00-1.10

PH: 13.0-14.0

Free Alkalinity(piont): ≥20

Packing: 1000kg/barrel

Validity Time: One Year

Description

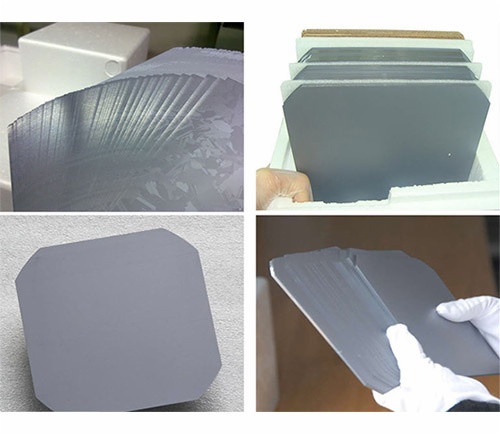

1. brief

The Junhe Type-1017 products are single-component products which are compounded mainly with potassium salt, corrosion inhibitor, complexant, detergent and surfactant by polymerization. The reagent grade potassium hydroxide provides saponification alkalinity. The polymerization corrosion inhibitor, complexant, detergent and surfactant provide the cleaning. This product has a very good performance in emulsifying,saponification and cleaning the animal oil, vegetable oil, mineral oil, suspension and grinding paste. It has strong stripping,complexing and cleaning effect on the metal ions. The cleaning of oil is 99% as detection. The stripping,comlexing and cleaning effect to the copper,iron and other metal ions. Meanwhile, Junhe Type-1017 products does not contain the phosphate,calcium, magnesium, iron, copper, lead and other harmful silicon metal ions and meet the EU ROHS requirements with good environmental protection and strong cleaning ability.

2. feature

1) Junhe Type-1017 products are high concentration single component products which can be continuously added with the automatic pump on the automatic line.

2) It does not contain phosphorus and meets the environmental protection requirements of EU ROHS.

3) It is a kind of low foam product and can be used in the spraying line and ultrasonic without foam overflowing.

4) The metal ion content does not exceed 50PPm except the potassium and sodium ions and it can meet the IT requirement of high precision.

5) good degreasing performance to meet the requirement of high-accuracy IT area.

3. use instruction

1) add 3/4 pure water in the cleaning tank first.

2) if using it in the manual line,it is suggest to add 5~10 kg of Junhe Type-1016 silicon chip cleaning agent per 1000 liter tank fluid. When cleaning the polishing and grinding paste silicon chip and silicon chip cut with recovery suspension, should add more doses within the 8 hours of shifting according the specification of each company. Of course, reduce the doses when keeping the silicon chip yield.

3) If adding continuously in the automatic line, open the tank with 1~2 kg Junhe Type-1017 silicon chip cleaning agent per 100 liter tank fluid and control the continuous adding according the automatic line silicon chip cleaning amount. For better cleaning effect,it is suggested to change each 1~3 shifts.

4) Generally each kilogram of Junhe Type-1017 silicon chip cleaning agent can clean more than 1000 silicon chips of 125# monocrystal silicon chips. Add according to this proportion. When cleaning the polishing and grinding paste silicon chip and silicon chip cut with recovery suspension, should add more doses. Of course, reduce the doses when keeping the silicon chip yield.

5) Then add the pure water till the operating level and heat to the required temperature and then can use it.

6) The silicon chip should be exposed as seldom as possible during cleaning in order to prevent the generation of flower parts.

4. notes

1) The crystal rod cannot be wet after linear cutting. If it cannot be cleaned in time, it will be better to be put in the suspension or cleaning agent (fully immersed)

2) Once the crystal rod after linear cutting is cleaned, it should be dealt with immediately. It is not allowed to make the silicon chip dry naturally during cleaning.

3) Must keep the silicon chip wet when degumming and should not make it dry naturally.

4) Close the foaming switch when ultrasonic cleaning the tank 1 and 2. after being on the shelves,open the foaming and mainly avoid the generation of fragment.

5) after each cleaning cycle is completed (such as shift turnover), change the pure water tanks of tank 5, tank 6, tank 7 and tank 8 thoroughly.

6) The cleaning personnel cannot touch the silicon chip during cleaning and must wear rubber gloves in case of finger print.

7) In order to keep the cleanliness of the silicon chip, the spraying cleaning time before degumming should be controlled within more than 30 minutes.

8) If there are the problems such as dirty chip and blaze during using, please contact with the technology service staff in time.

9) When discharging the product, it needs neutralization, flocculation and sedimentation and other simple processing. The product does not contain heavy metal and orthophosphate.

Technical Data

| Appearance | Colorless to yellowish liquid |

| Specific weight | 1.00-1.10 |

| PH | 13.0-14.0 |

| Free alkalinity(piont) | ≥20mg |

Product detail pictures:

Related Product Guide:

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of Online Exporter Zinc Flake Coating Machine - Single Group Silicon Slice Detergent JH-1017 – Junhe , The product will supply to all over the world, such as: The Swiss, Amsterdam, Iraq, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!