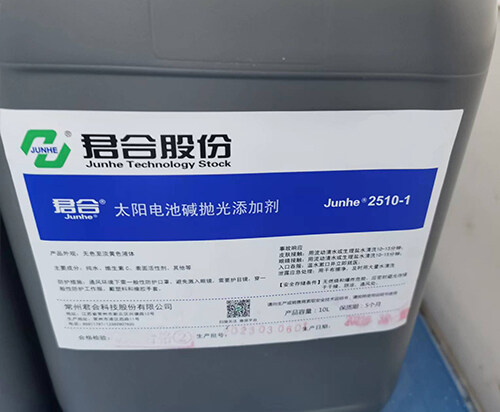

Features

1、 Purpose specificity

Specially used for welding ribbons of solar photovoltaic modules.

2、 Excellent strain adjustment

By adjusting the type or proportion of low, medium and high boiling point solvents in the formula, it can maintain excellent activity within the soldering temperature window.

3、High yield rate

The synergy of various penetrants and wetting agents reduces the surface tension between the wafer and the solder ribbon, reducing the false soldering rate and chipping rate.

4、 No cleaning required after welding

Low solid content, the copper surface is clean after welding, with less oily, crystallized and other residues, and no cleaning is required.

5、Good safety and environmental protection

Comply with RoHS and REACH standards, and meet the International Electro Technical Commission IEC 61249-2-21 halogen-free standard.

Performance parameters

|

Item |

Specification |

Reference standards |

|

Copper mirror experiment |

Pass |

IPC-TM-650 2.3.32 |

|

Refractometer concentration(%) |

27-27.5 |

Lichen high-precision refractometer(0-50) |

|

Welding diffusivity |

≥85% |

IPC/J-STD-005 |

|

urface insulation resistance |

>1.0×108 ohms |

J-STD-004 |

|

Water extract resistivity |

Pass:5.0×104 ohm·cm |

JIS Z3197-99 |

|

Halogen content |

≤0.1% |

JIS Z3197-99 |

|

Silver Chromate Test |

The color of the test paper is white or light yellow (halogen-free) |

J-STD-004; IPC-TM-650 |

|

Fluorine content test |

Pass |

J-STD-004; IPC-TM-650 |

|

Flux grade |

OR/M0 |

J-STD-004A |

|

Halogen-free standard |

Conform |

IEC 61249 |

Applications

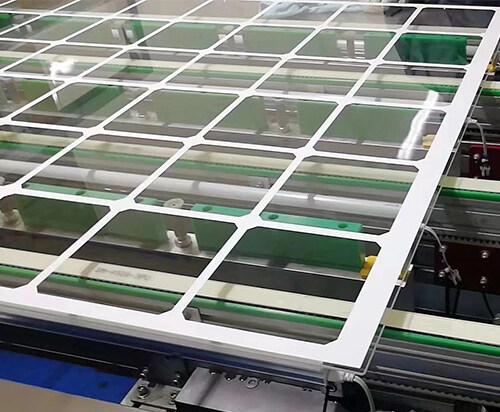

This product is generally suitable for P-type and N-type battery components; 2. This product is suitable for all brands of string welding machines.

Instructions

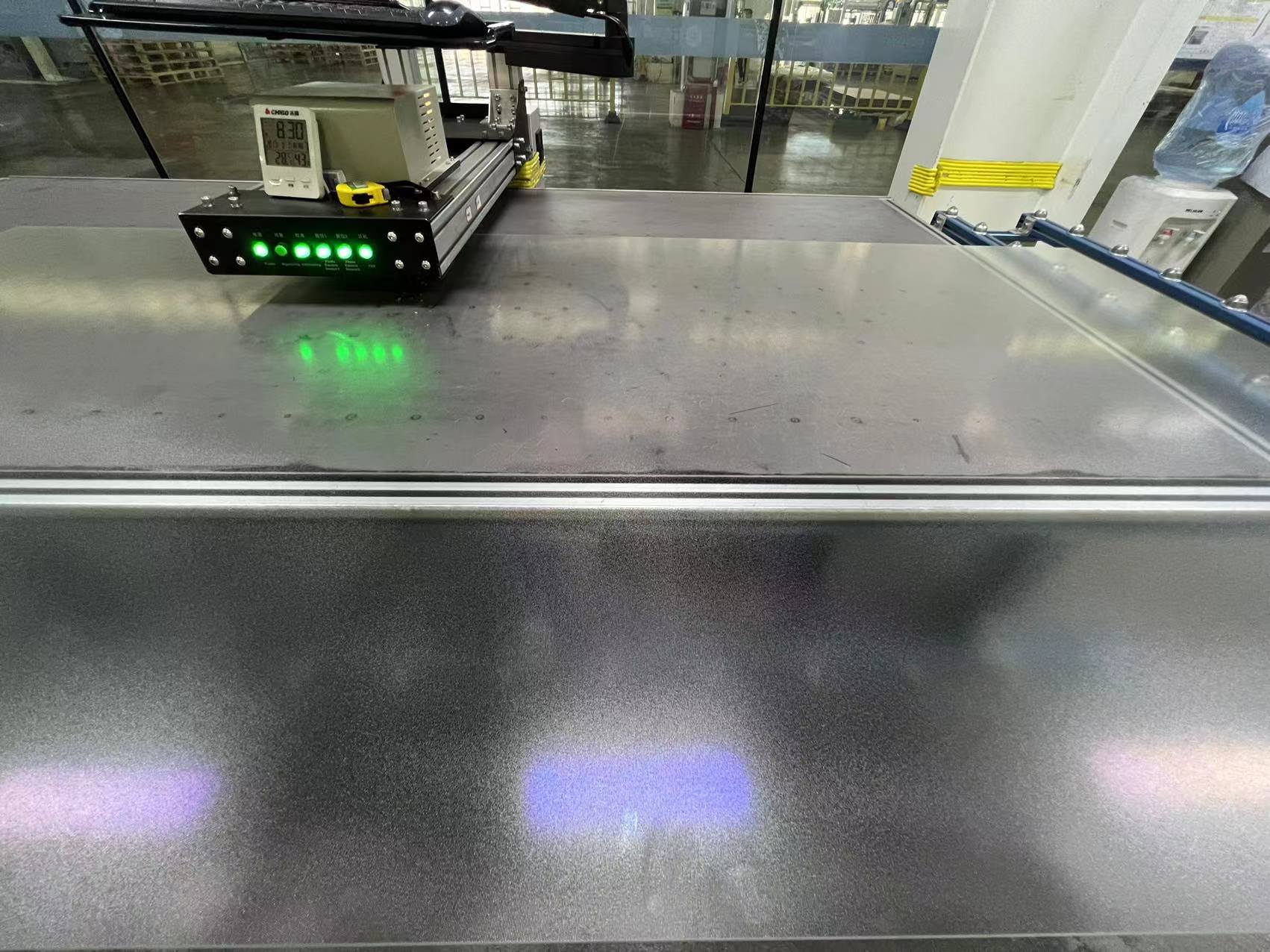

1、This product is widely used in mainstream string welding machines such as Siemens and Mavericks currently on the market.

2、Used in the optoelectronics and photovoltaic industries to replace potentially corrosive activated rosin-containing fluxes and other rosin-based fluxes. It is suitable for welding tinned solder strips, bare copper and circuit boards without pre-coating.

3、 It is suitable for automatic welding of solar cells coated by immersion or spray. It has high welding reliability and extremely low false welding rate.

Process control

1、The active ingredients of the flux can be controlled by controlling the specific gravity of the flux. When the specific gravity exceeds the standard value, add diluent in time to restore the set proportion; when the specific gravity is lower than the standard, restore the set proportion by adding flux stock solution.

2、When the welding strip is severely oxidized or the operating temperature is too low, the soaking time or the amount of flux applied should be increased to ensure the welding effect (specific parameters are determined through small batch experiments in the laboratory).

3、When the flux is not used for a long time, it should be stored in a sealed container to reduce volatilization or contamination.

Precautions

1、This product is flammable. When storing, keep away from fire sources and protect your eyes and skin.

2、In the workplace, when other welding is being performed at the same time, an exhaust device should be used to remove volatile substances in the air and reduce occupational health risks.

3、The flux after opening should be sealed first and then stored. Do not pour the used flux back into the original packaging to ensure the cleanliness of the original solution.

4、Please read the Material Safety Data Sheet carefully before using this product.

5、Do not throw away or dispose of this product casually. End-of-life products should be handed over to a specialized environmental protection company for disposal.