Posted on 2016-07-28 1.Dip spin coating

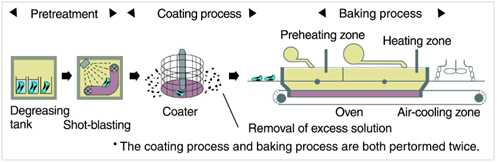

This is the most widely applied measure for coating fasteners and stamping parts of bolts, nuts, springs, screws. First, put the workpiece which after pre-treatment in the basket, dip coating, remove extra paint by centrifugal spinning, and then curing. According to different purpose of use, it can be coated with one time curing, but more commonly use two times curing method.

2.Spraying coating

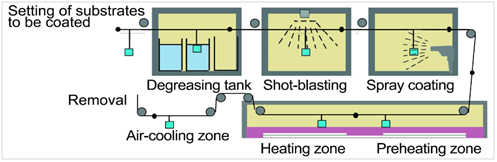

It applies to focus on the appearance of the workpieces. The workpiecet is placed on the hanger, after electrostatic spraying, drying process. Generally use one time coating one time curing method.

3.Leaching

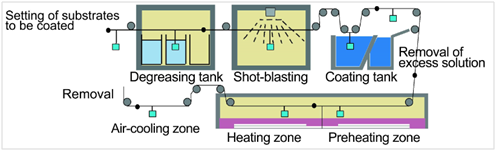

Big workpiece can’t put in the basket usually treated in this way. The workpiece hanging to put into the coating tank, diping then curing, usually just one time coating and curing. Rarely use.

Post time: Jan-13-2022