Posted on 2016-04-15

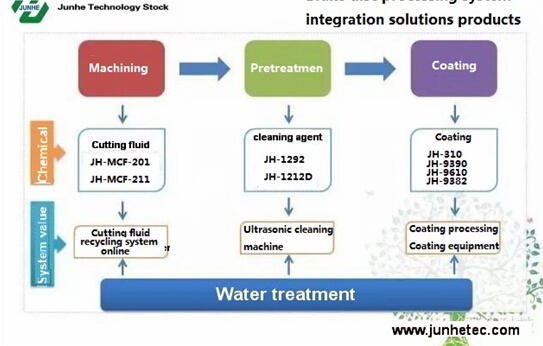

1, Cutting fluid products

JH-MCF – 201 General type microemulsion cutting fluid

Product synopsis: this product is a universal micro emulsive cutting fluid, by the lubricating oil, antiwear agent, anti-rust agent and other additives. Suitable for machining cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, and is widely used in all kinds of machine tools, machining center of cutting, grinding process. Single machine for liquid for liquid concentrate and the central cooling system all can apply.

Product features:

1, the product is a universal cutting fluid, wide application scope.

2, products for the micro emulsive cutting fluid, lubrication, cooling, liquid is easy to handle.

3, the product has good lubrication, cooling, cleaning and antirust performance.

4, the product can improve the surface finish of workpiece, ensure the workpiece and machine tool online antirust requirements.

5, good corrosion resistance, foam inhibiting and emulsion stability of long service life, reduce maintenance costs.

Packing specification: 25 kg plastic barrels

JH- MCF – 211 Microemulsion extreme pressure cutting fluid

Product synopsis: this product is a micro emulsified cutting fluid, extreme pressure of lubricating oil, extreme pressure and anti-wear agent, anti-rust agent and other additives. Suitable for processing cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, etc., and is widely used in all kinds of machine tools, machining center of cutting, grinding process. Single machine for liquid for liquid concentrate and the central cooling system all can apply.

Product features:

1, for oily liquid, belong to micro emulsified cutting fluid, extreme pressure by lubricating oil, extreme pressure and anti-wear agent, anti-rust agent and other additives.

2, good lubrication, cooling, cleaning and antirust performance.

3, improve workpiece surface finish to ensure workpiece and machine tool online antirust requirements.

4, good corrosion resistance, foam inhibiting and emulsion stability of long service life, reduce maintenance costs.

5, easy to liquid waste.

Packing specification: 25 kg plastic barrels, 200 kg of iron

2, The detergent products

Neutral cleaning agent cleaning agent series products of our company is a kind of, because of the function, performance, and the type, composition and content of their also slightly different.

JH-1292Neutral Cleaning Agent

Product introduction: 1292 is a kind of liquid, neutral cleaning agent, containing special surfactant and a certain amount of cleaning agent. Suitable for all kinds of metal impregnation and spray cleaning

Product features:

1. Can be used for aluminum and its alloy, steel parts, copper and its alloy impregnated, spray cleaning. Can also be used for ultrasonic cleaning, scrub and other cleaning method.

2. It contains help lotion and zwitterionic surfactant.

Packing specification: 25 kg plastic barrels, 200 kg of iron

JH-1212D Neutral Cleaning Agent

Product introduction: 1212 d is a kind of liquid that is close to neutral cleaning agent, containing special surfactant and a certain amount of complexing agent.

Product features:

1. Can be used for aluminum and its alloy, steel parts, copper and its alloy impregnated, spray cleaning. Can also be used for ultrasonic cleaning, scrub and other cleaning method.

2. It contains help lotion and zwitterionic surfactant.

Packing specification: 25 kg plastic barrels, 200 kg of iron

3, Coating liquid products

JH-310 Zinc flake coating

Product introduction: our company adopts advanced technology formula and foreign high-quality raw materials, product trademark for the JUNHE, is made up of zinc, aluminum and other inorganic water-based products, (the state intellectual property office of the invention patent number: ZL2003101061714), the product components of type automobile braking system for spraying demand specially developed, has better environmental adaptability and corrosion resistance, the product does not contain harmful heavy metals such as chromium, mercury, lead, cadmium, comply with the eu RoHS

Standard.

The coating liquid is made up of three components A, B, C:

A agent: mainly for ultrafine flake zinc, aluminum and water soluble organic fertilizer made of silver grey color paste;

B agent: for coating liquid fertilizer components, mainly containing aqueous solution of anticorrosive additives, special regulator, etc;

Agent: C for coating liquid viscous components, main ingredients for cellulosic-based white to yellowish powder.

Function characteristics:

1, environmental protection without cr

JH-310 for chromium-free environmental protection coating liquid, conform to the requirements of the joint venture brands, small impact on environment

2, salt fog performance is good

Neutral salt spray test: apply 2 baking 300 hours

3, high temperature resistant

JH-310 resistance to high temperature, 400 degrees Celsius, brake disc brake which is caused by high temperature will not affect coating

4, to enter the public liquid coating supplier list

I JH-310 is approve by the same company, the customer can be at ease use

Packing specification: A dose of 10 kg or 20 kg drum packaging; B agent for 20 kg plastic barrels packaging; C agent for small iron drum packaging. (special circumstances packaging according to customer requirements)

JH-9390 Zinc flake coating

Product introduction: our company adopts the international advanced technology formula and foreign high-quality raw material development and production of 9390, a major breakthrough in the technology, is the first choice for replace imported products.

The coating liquid is made up of three components A, B, C:

A: mainly for ultrafine flake zinc, ultrafine flake Al and ethylene glycol silver compounds consisting of mortar.

B: in order to apply liquid solvent components, mainly for the aqueous solution contains Cr6, + orange red.

C: for coating liquid viscous components, mainly for fiber white or yellowish powder.

Product features:

Film is silvery white, surface finish, besmear again good, salt fog resistance more than the national standard, the finished liquid anti-aging cycle is long, the same more machining process conditions.

Packing specification: A agent for 16 kg drum packaging; B agent is 24 kg plastic barrels packaging; C agent of 1-5 kg drum packaging. To change the packing (special circumstances)

JH-9382 Zinc flake coating

Product introduction: our company adopts the international advanced technology formula and foreign high-quality raw material development and production of 9382, a major breakthrough in the technology, is the first choice for replace imported products.

The coating liquid is made up of three components A, B, C:

A: mainly for ultrafine flake zinc, ultrafine flake Al and ethylene glycol silver compounds consisting of mortar,

Zinc diameter to thickness ratio of 60 ~ 100.

B: in order to apply liquid solvent components, mainly for the aqueous solution contains Cr6, + orange red.

C: for coating liquid viscous components, mainly for fiber white or yellowish powder.

Product features:

Film is silvery white, surface finish, high corrosion resistance, good coating again.

Packing specification: A agent for 16 kg plastic barrels packaging; B agent is 24 kg plastic barrels packaging; C agent for 5 kg drum packaging. Package (special case in a VAT)

System value

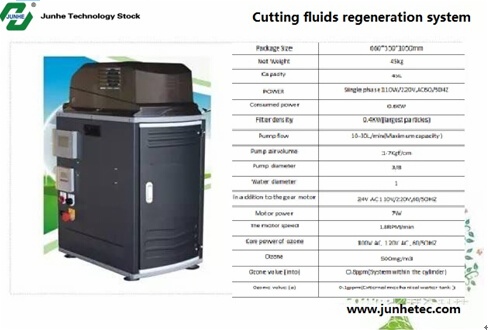

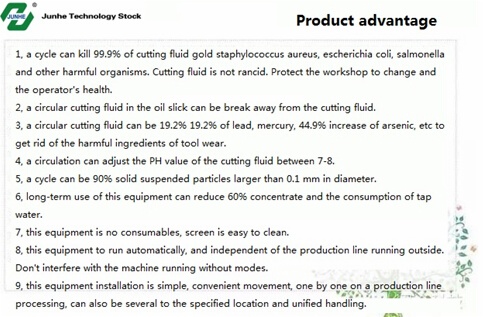

1, Cutting fluids regeneration system

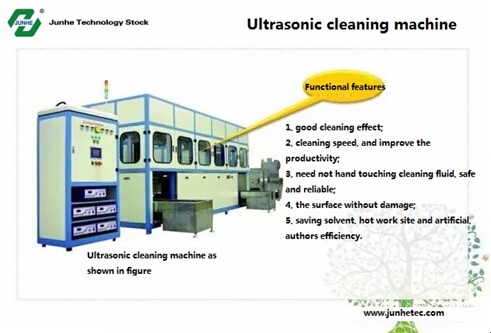

2, The ultrasonic cleaning machine

3,Zinc flake coating line

Post time: Jan-13-2022