Cleaning cycle: 80 pcs/4 mins

Surface tension after cleaning: ≥34Nm

Assembly and transfer time: <30s/5 pcs

Step positioning accuracy: <1mm

Running speed: 16mm/min

Paints and painting environment temperature: 20℃±2

Spraying time: <15s

Film thickness: 6 to 15μm

Handling time: <25s

Curing temperature: 250℃(adjustable)

Drying time: 25-30 mins

Can store 114 empty boxes

Handling total air volume: 68,000 m³ /h

Zeolite wheel concentration ratio: 1:10

Description

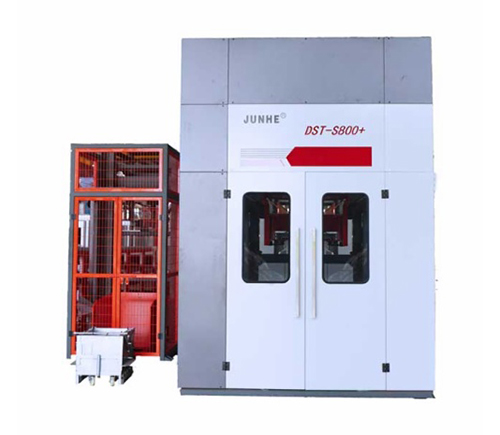

1. Junhe BOSCH Injector Precision Spray Line

Patented products, intelligent design, energy saving and environmental friendly, quality controlled, no blind area. Suitable for coating cylindrical and tubular rotating parts.

2. Automatic loading and unloading, use vacuum hydrocarbon cleaning agent, online separation and filtration, recycling, zero emissions.

3. Different workpieces, fixtures and shades can be customized.

4. Intelligent chain conveyor system, Dual servo synchronous drive, closed-loop control.

5. Wagner automatic paint matching system, customers can set matching parameters, constant temperature, real-time monitoring

6. Multi-position robot synchronous spraying, higher accuracy, dry paint mist treatment system, more environmentally friendly, FESTO Valve island closed loop control, more evenly.

7. Automatic feeding and transferring by robot, high production efficiency and low labor cost

8. Set temperature parameters on demand, step transmission, improve energy efficiency, high degree of automation

9. Automatic handling, oil drainage, vacuum oil removal, to meet the overall line beat.

10. Empty box storage transfer roller line, whole process of control, meet the production requirements.

11. Constant temperature and humidity, sequential storage , first in, first out

12. Circulating cooling system, zeolite wheel +RTO waste gas treatment system, waste gas recycling, more environmentally friendly

13. Electrical control adopts communication mode, which is more efficient and convenient, and supports remote fault diagnosis, monitoring and update. Provide - fixed, mobile, remote and other multi-terminal control platform

Meet - customer's different demands