High definition Corrosion Resistant Coating For Aluminum - Black Dacromet Coating Paint Top Coat JH-9321 – Junhe Detail:

Payment & Shipping Terms:

Minimum Order Quantity: 100 Kilograms

Price: Negotiable

Packaging Details:30kg/ plastic barrel

Delivery Time: Ten days after receipt of advance payment

Supply Ability: 2 Tons per Day

Color: Black

PH: 8.0-9.0

Viscosity: ≥50s

Thickness Of Dry Film: 10-20 (micron)

Hardness: ≥1

Adhesion(degree): ≤1

Description

1) The main ingredient is water-base inorganic silica , mixed with corrosion protection assistant.

2) The product cost is low.

3) The coating layer is smooth, weak acid and alkali resistant.

Technical Data:

| No. | Item | Data |

| 1 | Appearance | Black , fine and smooth |

| 2 | Viscosity | ≥50s |

| 3 | PH | 8.0-9.0 |

| 4 | Thickness of dry film | 10-20 (micron) |

| 5 | Hardness | ≥1 |

| 6 | Adhesion(degree) | ≤1 |

| 7 | Bend | 1(mm) |

| 8 | heat and humidity resistance | 240 (h) |

Instructions and attention:

1. Dip coating, Spray coating etc;

2. It should be stirred fully befor usage; distilled water or deionized water can be used to adjust viscosity; Operating viscosity: 30-60s.

3. When the environment humidity higher than 85%,can add certain industrial alcohol to adjust viscosity;

4. Curing condition: 80℃/10min+140℃/30min;

5. Cleaning appliance: running water can be used;

6. Avoid acid substances, or polymerization and deterioration will happen;

7. This product can be used alone, the coated surface request oil free, dust free and dry, the better make pre-treatment of degreasing, derusting, and phosphating.

Processing method:

A 1 base-coat+ 1 Top coat

B 2 base-coat+ 1 Top coat (heavy corrosion protection)

Professional Electroplated Zinc Coating , Black Dacromet Plating Alkali Resistant

Process Parameter:

Dip Coating Temperature RT

Operateing Viscosity 45-60 S

Centrifuge 210~270 RPM/min 10s X 4-8 times

( Centrifuge device can not be mix used with spin dyrer )

Spray Coating Temperature RT

Operateing Viscosity 30~40 S

Curing: 80℃ 10min + 140℃ 20—30min

Corrosion protection of b process flow

Corrosion resistance: ≥1500h (NSS)

Sea water resistance: 25℃≥1500h

Technical Data

| No. | Item | Data |

| 1 | Appearance | Black , fine and smooth |

| 2 | Viscosity | ≥50s |

| 3 | PH | 8.0-9.0 |

| 4 | Thickness of dry film | 10-20 (micron) |

| 5 | Hardness | ≥1 |

| 6 | Adhesion(degree) | ≤1 |

| 7 | Bend | 1(mm) |

| 8 | heat and humidity resistance | 240 (h) |

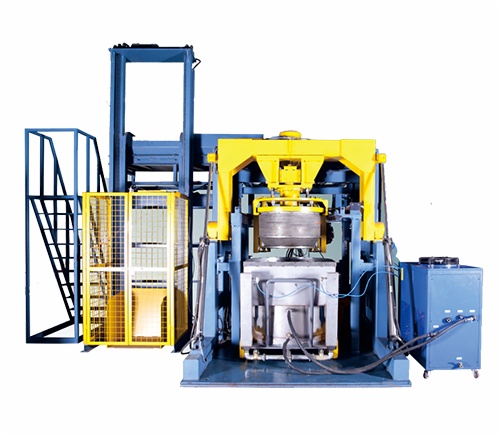

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for High definition Corrosion Resistant Coating For Aluminum - Black Dacromet Coating Paint Top Coat JH-9321 – Junhe , The product will supply to all over the world, such as: Spain, Cyprus, Plymouth, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.