Main Composition

|

Composition |

Contents |

CAS No. | EC No. |

|

Pure water |

90-92% |

7732-18-5 |

231-791-2 |

|

Sodium carbonate |

1.0-3.0% |

5968-11-6 |

207-838-8 |

|

Acrylic block branched compound |

1.0-2.0% |

/ |

/ |

|

Surfactant |

1.0-1.5% |

25155-30-0 |

246-680-4 |

|

Preservative acid |

0.1%-1.5% |

137-40-6 |

205-290-4 |

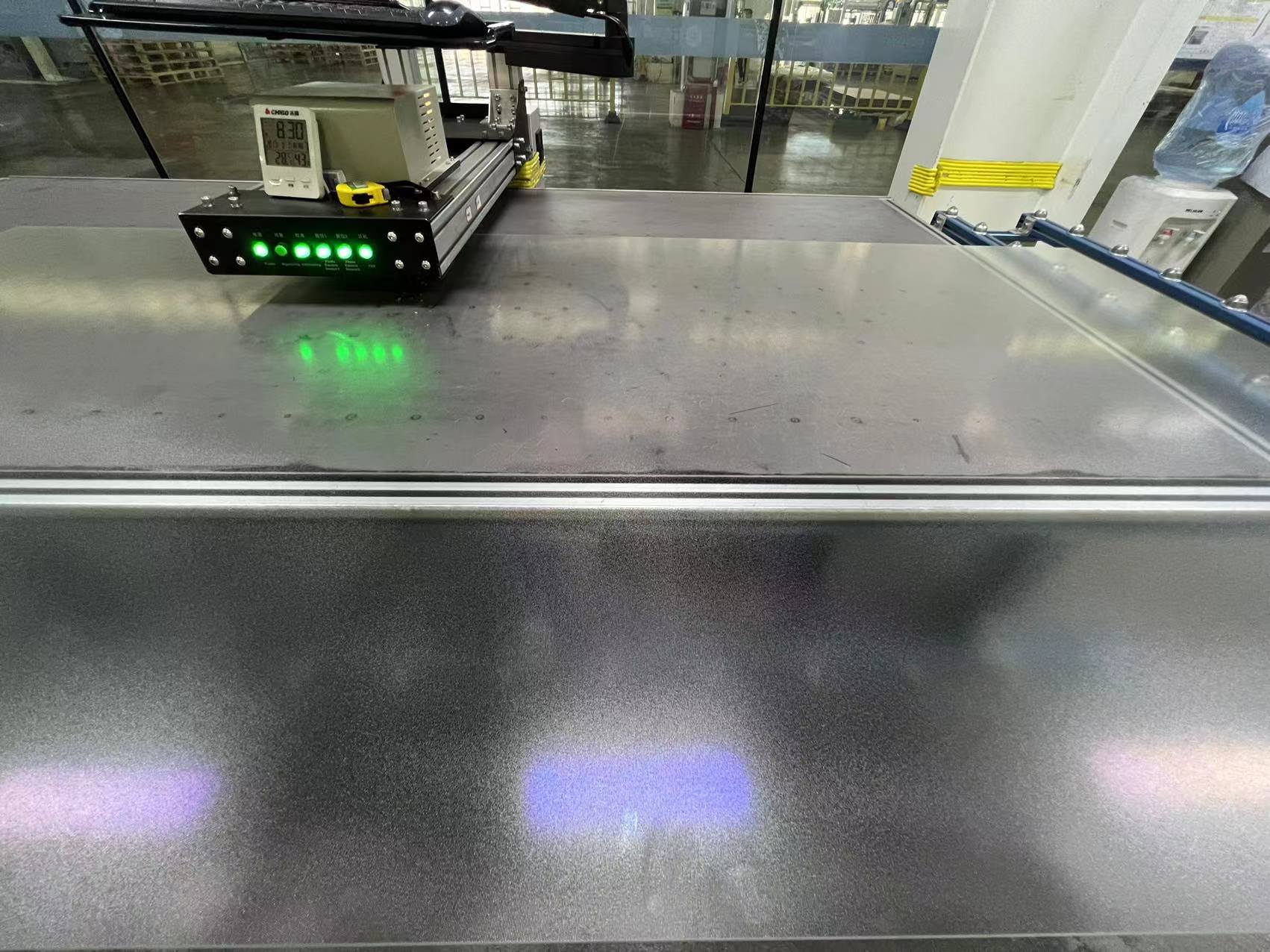

Features

1. High environmental protection level: selective etching can be achieved without the use of organic bases such as TMAH;

2. Low production cost: Compared with the common pretreatment using hydrofluoric acid/nitric acid on the market, the production cost is greatly reduced;

3. High etching efficiency: Compared with the Perc battery process, the conversion efficiency is increased by more than 1.2%;

|

Wafer size |

Appearance |

Photoelectric conversion |

Life |

|

210 |

The etching surface is normal and the positive film has no corrosion. |

24.4%~24.6% |

240+ |

Technical Parameters

|

/L First liquid dispensing

|

/L Liquid infusion |

/L Intermission-draining |

Temperature/degree |

Reaction time/second |

|

|

48%KOH |

8~10 |

0.3~0.45 |

5~7 |

63~64 |

100~200 |

|

Additive JH2570 |

2.0~4.0 |

0.18~0.21 |

|||

|

Pure water |

440.0 |

/ |

These properties may vary depending on the single crystal wafer, process, batch, and size.

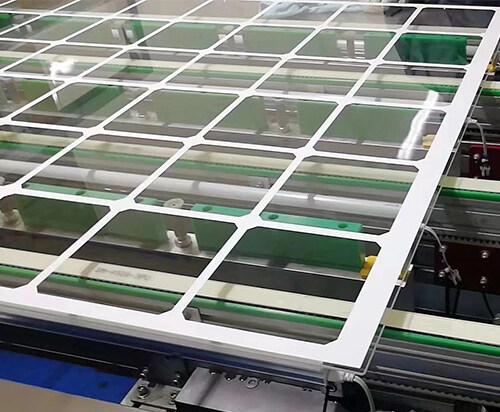

Applications

1、This product is aimed at removing amorphous silicon coating from topcon cells;

2、 Suitable for monocrystalline cells of 210, 186, 166, and 158 specifications.

Product Features

|

No.

|

Parameter

|

Main parameters and project indicators |

|

1 |

Color, shape |

Colorless to light yellow transparent liquid |

|

2 |

PH value |

7.0-10.0 |

|

3 |

density |

1.05-1.5g/ml |

|

4 |

Storage conditions |

Store at room temperature away from light |